Description

Características

- Durable and easy to decontaminate.

- Narrow 16 mm (5/8″) diameter probe.

- Sturdy free-standing reel with carrying handle.

- Accurately laser marked each mm.

- Lengths to 300 m.

- Markings certified traceable to national standards.

- CSA certified intrinsically safe for hazardous locations.

- CE Standards & ATEX certified.

Determination of non-aqueous phase (LNAPL) lightweight (floating) and non-aqueous phase dense (sinking) liquids (DNAPL) is quick and easy. The factory sealed probe is pressure proof (up to 500 psi) and tapes are available in a length range of 30 to 300 m.

The 16mm diameter probe allows easy access through tight spaces and into narrow wells. The probe is designed to be used in different monitoring applications. A mini interface model 122M is also available.

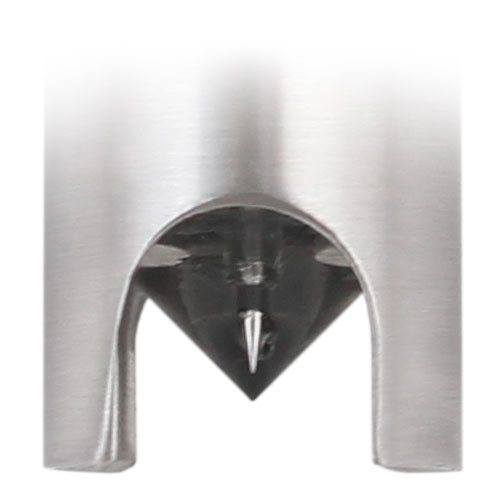

P8 probe

The 122-interface probe uses the P8 electrode, 16mm in diameter, is stainless steel and pressure tested up to 500psi. The beam is emitted from a Hydex cone shaped tip. The tip is protected by an integral stainless-steel shield and is excellent for the vast majority of oil and oil derivative monitoring situations.

Flat laser marked ribbon

The flat ribbon is extremely accurate, traceable to NIST and EU measurement standards.

The easy-to-read marks on the 10mm flat ribbon are permanently laser marked. The “dog bone” shape of the tape prevents it from sticking to wet surfaces in the wells. It is resistant to most chemicals, and the smooth surface of the tape is easy to handle clean.

LM2: feet and tenths of an inch, with marks every 1/100 feet.

LM3: meters and centimetres, with marks every millimetre.

Additional equipment

Each standard size probe is provided with a ground pole, a cleaning brush, and a tape reference / guide. A carrying case is optional.

The tape guide can be used to provide support for a small reel in the well casing. It acts as a reference point that allows repeatedly accurate measurements, ensures that the probe hangs in the center of the well, and protects the tape from damage.

It is essential to use the ground pole to guarantee the safety and correct operation of electronic devices in all applications.

Model 122 is approved by QPS for use in Class I, Div. 1, Groups C and D hazardous locations according to CSA standards and is ATEX certified under Directive 94/9 / EC as II 3 G Ex ic IIB T4 Gc

Funcionamiento

Product (non-conductive liquid) = constant light and tone

Water (conductive liquid) = flashing light and tone

To detect liquids, Solinst interface probes use an infrared light beam and detector. When the probe enters a liquid, the beam is refracted away from the detector that activates an audible tone and light.

If the liquid is an oil or non-conductive product, the signals are constant. If the liquid is conductive (water), the conductivity of the water completes the conductivity circuit. This overrides the infrared circuit, and the tone and light are intermittent.

The electrode of the interface probe 122 provides an accuracy of up to 1.0 mm. The high precision allows the probe to detect the smallest trace of oil on the surface of the water.

Electronic elements include automatic circuit tests when the “On” button is used; 120 hours of battery life; Clear, high-precision signals. The circuits are powered by a single standard 9V battery, located in the easily accessible tray on the front cover of the front plate.

Infrared refraction is used to detect liquids and conductivity to distinguish water. The optical and electronic sensors are precisely aligned at the same zero point.

Obtaining product measurements

To measure the thickness of a layer of product, lower the probe into the well until the signal is activated. If there is an oil-product layer on the water (LNAPL), the light and tone will be constant, indicating an air-product interface.

Read the depth on the permanently marked tape. Lower the electrode further into the water, where the signals become intermittent, then remove it and obtain a reading at the product-water interface. The thickness of the product layer is then determined by subtracting the first reading from the second.

If there is only water in the well, there will only be flashing signals (water). The presence or absence of dense (sinking) layers in non-aqueous phase (DNAPL) is determined by lowering the electrode back to the bottom of a well.

If both constant tone and light return, this indicates a non-conductive liquid. Measure the depth and continue lowering the probe until it bottoms out and the tape is loose.

To determine the thickness of the DNAPL layer, subtract the first reading from the bottom depth.

Funcionamiento sonda 122

FAQ

Troubleshooting

When the instrument is turned on you will see a steady red light (no audible alarm).

- Indicates there is a connection problem. Contact Envirotecnics for more information on how to resolve the problem.

The instrument does not turn on (there is no start tone)

- Replace the battery.

- Check the polarity of the battery in the compartment: make sure that the + and – symbol on the battery and in the compartment match. The electrode can be damaged by an inverted battery.

- The ON / OFF button may be faulty. Contact Envirotecnics.

When the instrument is turned on, it immediately emits the hydrocarbon tone or the intermittent water tone.

- The probe sensor may be dirty. Clean it according to cleaning and maintenance instructions.

- Water has been able to seep into the electrode. Stir it carefully, keeping the cables connected. Dry and clean it, and inspect the o-ring (o-ring), replace if necessary and / or lubricate with silicone. To avoid cuts or damage to the cables, make sure they are tucked inside the probe body when you are ready to replace it. See probe replacement instructions.

- The tape may be damaged. Clean the tape and watch for cuts or damage. If necessary, replace the tape. To maintain Intrinsic Safety Certification 122, do not make splices or repairs to the tape. Contact Envirotecnics for assistance.

- The reel or probe circuits may be damaged. Contact Envirotecnics.

The instrument does not detect liquids

- Check the battery. Replace it if necessary.

- Clean the electrode tip following the cleaning and maintenance instructions.

- The electrode may be damaged. Contact Envirotecnics.

The instrument detects “hydrocarbon” as “water”

- Note that this can happen if the electrode enters the hydrocarbon too quickly and therefore draws water with it. Thoroughly dry the tip or shake it gently and try again more slowly.

- The hydrocarbon may have been degraded or is now altered enough to become an emulsion. If you have a detectable level of conductivity, it will read water. Wait for it to stabilize and try again.

The instrument does not detect water

- Clean the tip of the electrode. Follow cleaning and operating instructions.

- The water may be pure and non-conductive, or the hydrocarbon may coat the probe, in which case, briefly shake it in the water column to remove the hydrocarbon.

- The probe circuits could be damaged due to high (static) voltage in the well. Always use the ground pole. Contact Envirotecnics.