Description

Características

Detailed data in 3 D

When multiple Waterloo systems are used at one site, they allow detailed three-dimensional information on groundwater to be obtained at a reasonable cost. An advantage is the smaller number of drilled wells and reduced monitoring times.

The modular system can be customized for the unique requirements of the project. This allows areas located at desired depths to be monitored using options suitable for bedrock, overburden, or combination applications.

Discrete zone monitoring is the only means of obtaining accurate data for site interpretation and evaluation. Multi-level cross sections provide the detailed data needed to calculate mass flow and roughly assess risk to recipients.

Operation:

Installation of the Waterloo system begins with the connector on the base and the lower sections. The components are joined in the required order. As each new port positions a new monitoring tube, a dedicated pump and / or transducer is connected to it. The following components are threaded onto this pipe, building the casing rope until the Waterloo system assembly is complete. Generally, installations are completed in one day using a team of 3 to 4 people.

Advantages of the 401 system

- Detailed depth of flow and concentrations.

- Reduced costs of the project.

- Reduced purge and sampling times.

- Fewer wells drilled.

- Reduced alteration of the site.

- Various monitoring options.

- Isolated sampling in discrete areas with contaminants.

- High resolution characterization of the site.

Why Multiple Levels Provide a Clearer Understanding of Subsoil Conditions

Monitoring a series of discrete isolated intervals at various depths in a single hole captures higher quality data. Detailed information provided by multiple levels in the form of horizontal and vertical flow, along with sampling discrete areas to detect contaminants, is necessary to make accurate site assessments.

- Improves site assessments and risk management

- Multiple levels provide high resolution data to enter into more representative conceptual models of the site.

- Multi-level cross sections through a groundwater flow step provide the best data to use for Mass Flow calculations. This has proven to be an important tool for site evaluations that require actual estimates of maximum contaminant concentration / receptor risk.

- Optimize on-site remediation performance using detailed 3D data from a multilevel series. Subsequently, cross-sections can be used to assess the success of the chosen remediation option and improvements.

- The economy makes sense.

- Proven cost reductions for drilling and sediment removal.

- The costs of field staff time and disposal are low when purge volumes are reduced. The discrete span spanning a multi-level port results in smaller bleed volumes, quick responses to level changes and is ideal for low flow sampling techniques.

- Overcome biases with filter wells for a long time.

- The mixture of pollutants on long filters distorts the vertical variations which produces an underestimation of the aerial extension of the booms and of the true concentration of pollutants.

The vertical environmental flow within the well has the potential to transmit contaminants to uncontaminated areas.

Funcionamiento

System design explained

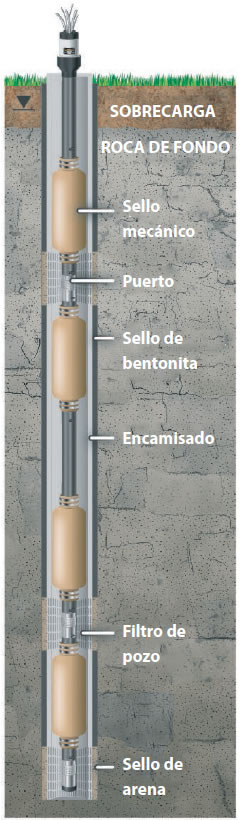

The Waterloo system uses modular components that form a sealed casing cord of various casing lengths, mechanical seals, ports, a base connector, and a surface manifold. This allows precise placement of ports in exact monitoring areas.

The monitoring pipeline connected to the stem of each port, individually connects that monitoring area to the surface. The standard system is made of 2 “(50mm) Sch. 80 PVC for 3” – 4 “(75 – 100mm) perforations and uses 3ft (915mm) length mechanical seals. Stainless steel components and PTFE tubes are available.

Modular sealing gaskets *

The Waterloo system’s easy-to-apply gasket design uses a nylon cable for reinforcement and an o-ring (O-ring). This makes the joints reliable and leak-proof so that the core of the Waterloo’s casing rope is

isolated from external forming waters. Groundwater can only be accessed through port stems and connected monitoring equipment. This hermetic seal prevents contact between the mechanical seal inflation water inside the casing and the formation water outside the casing.

Custom Wellhead Manifolds

The manifold completes the system on the surface. Organize, identify and coordinate the pipe and / or cables from each monitoring area.

The manifold allows connection to each dedicated transducer at a time and a simple one-step connection for pump operation. When dedicated pumps are selected, a single wellhead allows individual zones to be purged separately or many zones to be purged simultaneously to reduce field times.

Monitoring system

The Waterloo system monitoring ports are made of 316 stainless steel. Mechanical seals isolate the ports in each desired monitoring zone and connect individually to the surface manifold with narrow diameter tubes. In this way, the water enters the port, passes through the stem upwards into the monitoring tube connected to the stem to its static level.

A sampling pump or pressure transducer can be specified for each monitoring zone by connecting the port stem. Dual-stem ports are available to allow both sampling and hydraulic head measurements from the same port. Alternatively, the monitoring line can be left open to allow sampling and hydraulic head measurements with portable equipment.

Aplicaciones

Multiple port installations

- Overburden or bedrock installations

- They allow monitoring multiple zones in any geological scenario

- Installations in areas of groundwater or fords

- Waterloo permanent mechanical seals

- Designed for bedrock or casing holes

- Designed for permanent stamps

The Waterloo system is flexible to suit your design criteria. Each Waterloo system is customized to meet the unique monitoring needs and site subsoil conditions:

- rock bottom or overhead applications

- monitoring in groundwater or forbidden areas

Mechanical seals and ports are precisely installed so that each discrete isolated area of interest can be monitored, eliminating all cross-contaminated areas in the area.

A Waterloo system that fits your application

Your Waterloo system can be designed to fit your unique application and site requirements.

Each design can be based on your:

- drilling method.

- areas of interest.

- preferred monitoring methods.

- cost considerations.

- depth, diameter and type of hole.

- site geology.

Its system may be designed to suit the drilling size and depth, whether or not there is a casing present. You can decide on the number of zones to monitor and the depth in which these zones will be located. Select your preferred monitoring options and any necessary supplies you may require.

Monitoring options

- Dedicated sampling pumps and / or pressure transducers

Each monitoring port can be matched with a dedicated sampling pump and / or pressure transducer. This maximizes the speed within which each set of data can be obtained and eliminates the need to decontaminate and repeatedly download portable instruments. Sampling pumps are suitable for sampling many types of contaminants including VOC (Volatile Organic Compounds).

The purge volumes are very small. Simultaneous purging can be performed with dedicated pumps in all zones. Dual-stem ports allow a pump and transducer to be located at exactly the same level.

- Open pipe

The most basic version uses open tube connected to each port. This option allows monitoring with a portable sampler and a narrow diameter water level meter. This provides a very economical and flexible device for multi-level monitoring.

- Combination of open pipe and dedicated equipment

A third option is to choose a combination of open pipe and dedicated equipment in different areas. This method combines the advantages of less expensive portable equipment for shallower areas and more time-consuming dedicated equipment for deeper areas.

- Water level monitoring only

The Waterloo system can be composed only with pressure transducers for pressure monitoring in up to 24 discrete zones.