Description

Características

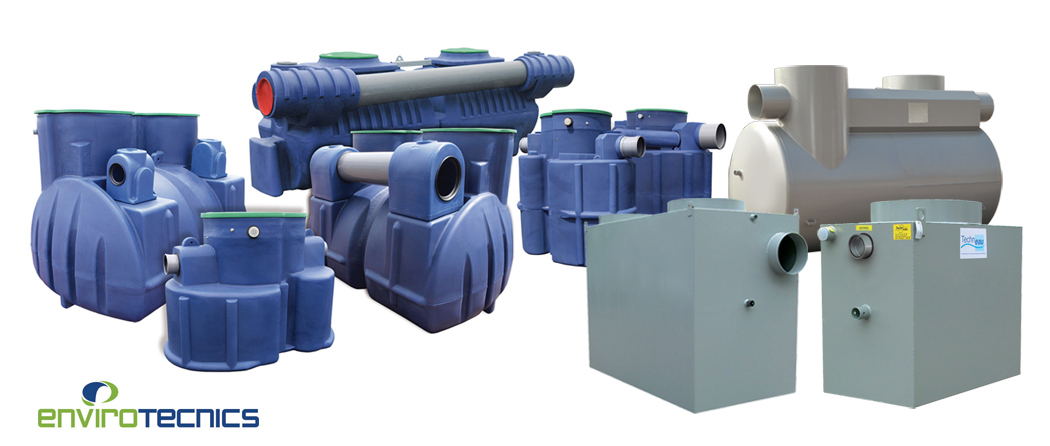

Components

Decanter

This compartment, located before the separation chamber, is intended to decant the heavy materials (sludge).

Separator

The separating compartment of the holding chamber allows free hydrocarbons to rise to the surface. Thus, it allows the storage of recovered hydrocarbons.

The bypass

A hydrocarbon separator with bypass allows absorbing the most important flows in the event of a storm, up to 5 times the nominal flow. A nozzle allows to treat the expected nominal flow rate for which it has been designed.

The automatic shutter

Each device in the range is equipped with an automatic shutter device in order to avoid any rejection of the natural environment. Its operating principle is also based on the difference in density between water (density 1) and light liquids (density 0.85). Thus, the automatic shutter floats in the water while, in the hydrocarbons, it sinks. When the hydrocarbon layer is thick enough, the exit of the device is plugged.

The coalescing lamellar cell

A coalescing system is used in order to improve the scrubbing performance of the device. This procedure allows to obtain a rejection level lower than 5 mg / l. The effluent travels from the bottom up, favouring the flotation of free hydrocarbons with a density of 0.85. The hydrocarbon particles suspended in the water stick to the back of the lamellae and form a hydrocarbon film that migrates from the bottom up.

Classification in the attached catalogue

- Decanter & Coalescing Filter

- Decanter, coalescing filter & bypass

- Large decanter & Coalescing filter

- Coalescing filter

- Decanter, coalescing filter and pump tank

- Acid neutralization tank

- Hydrocarbon separators Sizes> 35 l / s

- Decanter, Coalescing filter

- Decanter, coalescing filter, by-pass

- Rainfall intensity

Normative

The production of hydrocarbon separators is subject to the EN 858 standard.

UNE EN 858-1

Principles for the conception, manufacture and testing, marking and quality control.

UNE EN 858-2

Installation of light liquid separators.

Funcionamiento

It is based on the difference in density between the elements present inside the separator. Light liquids, with a density of 0.85, rise to the surface while heavy materials, with a density of 1, settle to the bottom of the device.

Aplicaciones

Recommendations

Attention to undersized spacers:

The observation of a correlation between the useful volume of the separator compartment and the purification performance shows that, below 90 seconds of residence time, the phenomenon of re-launching of the hydrocarbons upon discharge occurs.

The volume is not enough for:

- Store decanted hydrocarbons,

- Ensure a passing speed of less than 0.09 m / s,

- Avoid the creation of preferential flows.

- A poorly designed and poorly dimensioned oil separator is a time bomb.

- In the case of hydrocarbon pollution, your responsibility may be required by the authorities if they find that its origin is a poorly dimensioned hydrocarbon separator.