Description

Características

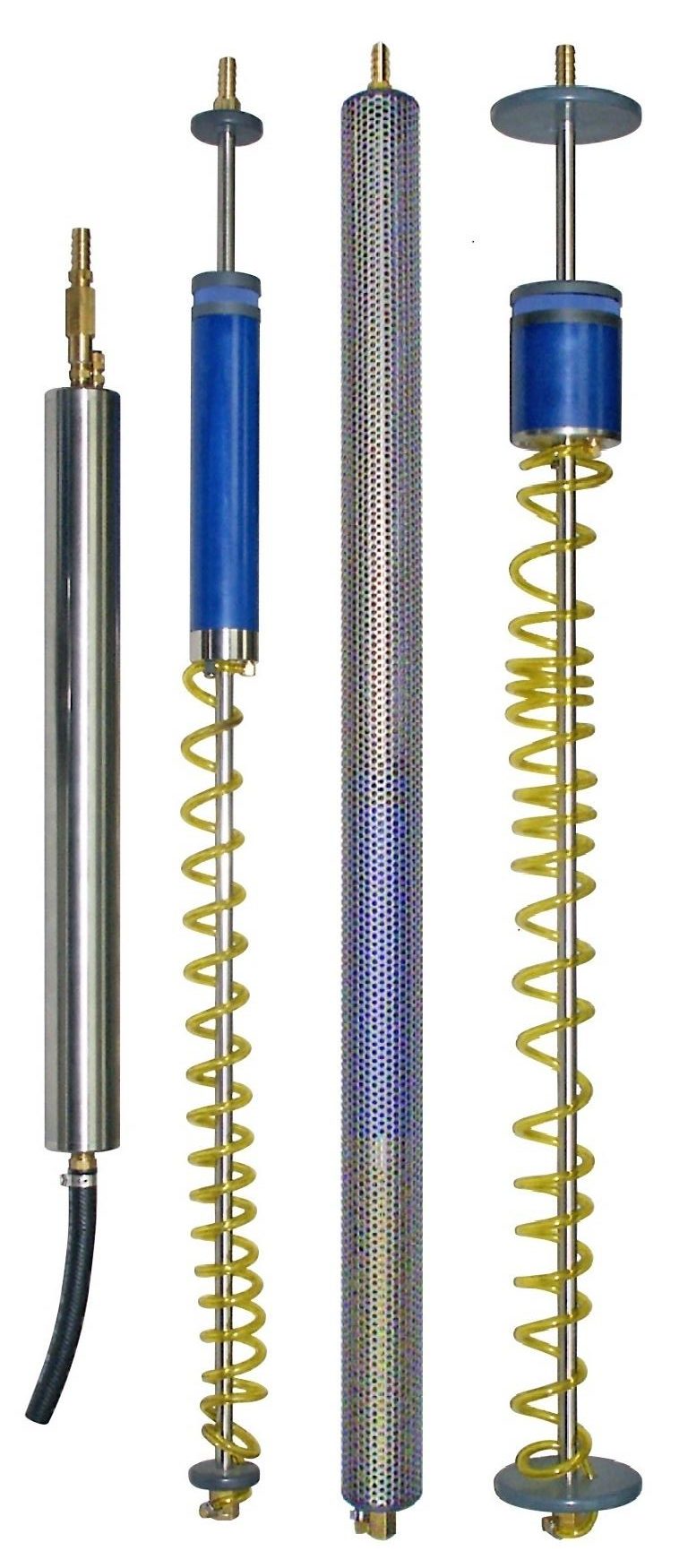

The AC Sipper uses a unique downhole pump to recover hydrocarbons through a floating oleophilic / hydrophobic intake membrane.

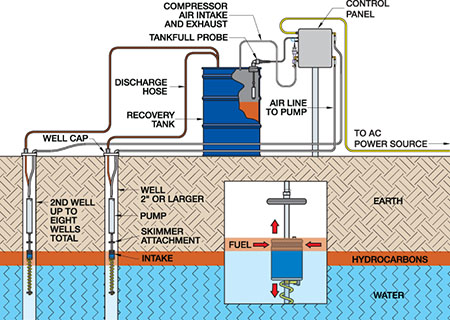

The Geotech AC Sipper can effectively extract fluids from depths up to 55m below ground surface and recover viscous hydrocarbons, such as 90 weight oil, when using the heavy oil skimmer.

This unique and flexible system can be configured for one to eight wells.

Heavy Hydrocarbon Skimmer Accessory for High Temperatures

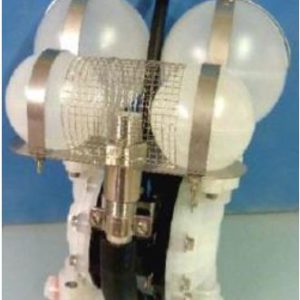

For high temperature well environments, Geotech provides a High Temperature and Heavy Hydrocarbon (HTHO) skimmer that incorporates an ultra-high molecular weight (UHMW) polyethylene intake float. The HTHO skimmer has stainless steel caps on the ends of a stainless-steel mesh that keeps debris out. The HTHO skimmer intake float has a 26” (66 cm) range of motion.

The heavy hydrocarbon skimmer attachment is designed to recover a range of fluids from gasoline to motor oil, reducing product down to .01 ‘(3mm) in 4” (10cm) diameter wells or larger. This option is more appropriate when the viscosity of the hydrocarbon is greater than the capacity of the filter screen (the screen can no longer pass the fluid hydrocarbon).

Funcionamiento

The AC Sipper recovers floating hydrocarbons (LNAPL) from wells using a powered pressure / vacuum pump. The standard Skimmer features a unique product intake assembly incorporating a density float and an oleophilic / hydrophobic membrane that differentiates between floating hydrocarbons and water. The skimmer floats just above the oil / water interface to collect and remove hydrocarbons from the well in an optional surface storage tank. Once the pump container is filled through the vacuum cycle, the pump reverses, pressurizes the system, and pumps the recovered fluid to the surface and into a storage container.

The AC Sipper is also available for recovery of heavy products (DNAPL) from wells when used with a fixed suction point.

Aplicaciones

This system is extremely flexible for use on a variety of sites, with skimmers available to recover product ranging from gasoline to oil. Whether it’s spills, leaks or escapes. It is used in industries, excavations, port areas, etc.

| Skimmer | |

| Applications: | 2 “(50mm) or larger recovery wells |

| Recovery rate | (757 ml) per cycle |

| Maximum operating depth | (55m) |

| Power requirements | 87 to 240 volts AC 2.7 at 1 amp (s) |

| Maximum pressure | 100 PSIG (7 bar) |

| Maximum vacuum | 20 “Hg @ MSL (50 mm Hg) |

| Control Box | |

| Operating temperature | 0 ° to 40 ° C |

| Storage temperature range | -29 ° to 66 ° C |

| Humidity | 90% non-condensing (max.) |

| Dimensions | 25.4cm x 45.7cm x 40.6cm |

| Approximate weight | 15.9 kg single channel 23.1 kg eight channels |

| Classification | NEMA 3R |