Description

Características

This Multilevel system is reliable, easy to install and inexpensive. This system provides the opportunity for field consultants to have a better three-dimensional perspective understanding of groundwater flow and the distribution of contaminants below the surface. The remediation strategy can be planned and more precisely defined, focusing efforts in the most effective way possible.

Advantages of the Multilevel System

- Provides accurate 3-D information from a study site.

- To understand the vertical distribution of pollutants.

- It allows documenting changes in the concentration and delineation of the polluting plume.

- Low cost compared to multiple single wells.

- Minimizes the alteration of the study site.

Research has shown that polluting feathers are generally thin and highly layered. It has also been possible to document that the traditional monitoring wells that have long areas covered with meshes, mix the groundwater throughout the entire area. The result is that the true concentration of the pollutant and its distribution are masked. Multilevel with short mesh areas overcome this problem. High resolution information provides unprecedented definition of contamination below the surface, and as a result more effective and less costly remediation can be carried out. The quality of the water sample obtained in wells with short meshes, provides much more justifiable information.

Multichannel piping

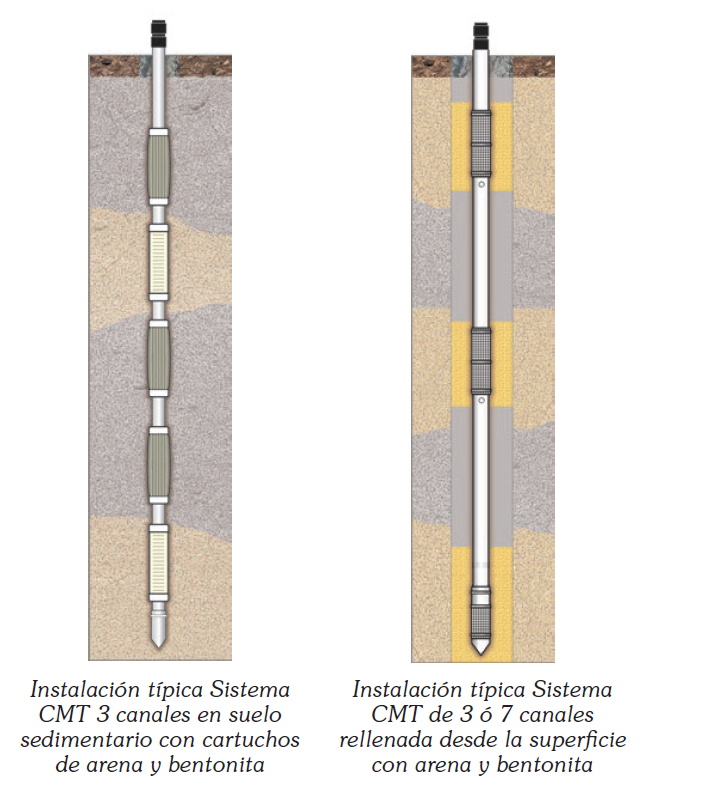

A Multilevel well that uses a continuous length of Multichannel pipe has the advantage over other Multilevels that have no joints. This significantly reduces installation time and cost while increasing system reliability. The CMT is a very simple to use and convenient system, since it provides complete flexibility for the placement of the monitoring ports.

Funcionamiento

The number and location of monitoring ports can be determined in advance, or after drilling the hole. The Port Cutter Guide is used to create the monitoring port on one of the channels, at the specified depth for monitoring. A plug is placed and sealed in the channel just below the port opening over which a stainless-steel mesh is placed to prevent the entry of fine material (sands). Each channel is sealed to the end of the pipe to prevent cross contamination between the monitoring zones.

Multilevel monitoring is essential

CMT Transects for Mass Flow Assessments

Multilevels provide reliable and detailed 3-D evaluation of monitoring zones. Important advantages include:

- Eliminates mixture of pollutants in wells with long meshes – resulting in averages of water / pollutant levels, mimics narrow areas of contamination and their vertical variations, overestimating the extent of contamination due to dissolution. Multilevel monitor discrete intervals.

- Prevents wrong conclusions due to flow between zones – cross contamination of contaminants can occur when different zones of the same well are not properly isolated. A properly insulated MLM prevents flow between zones.

- Provides information to calculate contaminant flow – calculating concentration, volume, and flow of contaminants helps determine the maximum concentration of the contaminant and the risk to receiving wells. The transverse placement of Multilevel installed across the groundwater flow path provides information to calculate the mass of the contaminant flow.

- Allows optimization for the design of the remediation system – The information provided by the Multilevel allows to define exactly the thickness, concentration and extension of the plume.

- Cost savings – cost savings on drilling and permits; due to the reduced diameter of the CMT channels, purge volumes and disposal costs are reduced; the efficient combination of low flow sampling and rapid response to level changes result in time savings in the field.

Water levels and samples can be accurately obtained using the following quality Solinst brand instruments:

- Level Meters: Model 102 Water Level Meter and model 102M Mini Water Level Meter, with coaxial cable, laser marked and narrow, with P4 tip 0.157 “(4mm) diameter, can be used for monitoring of water levels in any channel of the CMT. It is narrow enough to be used together with a pump in the same channel.

- Samples: The model 410 peristaltic pump which has the capacity to lift water from approximately 7.5 m depth. The Mini Inertial Pump can be used with low cost polyethylene hose at depths up to 15m or flexible PTFE up to 45m.

- The Model 408M Dual Valve Micro Pump (DVP) is ideal for low flow sampling of Volatile Organic Compounds. The Micro DVP is manufactured with a 9.5 mm (3/8 “) diameter PTFE or polyethylene hose. On the surface it has a manifold with a quick connector to connect it to the Solinst Electronic Controller with pre-programmed settings and a bypass to collect the sample. A manifold Multi Purge is also available for Micro DVP, for depths up to 73m (240ft).

Aplicaciones

- It allows to identify the vertical and horizontal distribution of pollutants with transversal monitoring.

- Ideal for installing shallow wells where water levels are high.

- Monitoring on unconsolidated land or rock beds.

- It allows evaluating the impact of water removal in construction and mining areas.

- It allows calculating the volume of pollutants and estimating the flow.

- Monitoring of processes by natural mitigation or remediation and documentation of changes.

- Monitoring of affected areas with napas, volatile organic, MTBE or Perchlorates.

- Allows the determination of the ideal zone for the placement of reactive barriers, Emitters and other remediation methodologies.

- Monitoring of vapors or groundwater.

- Helps optimize design and evaluate remediation performance.