AP3 Submersible Pneumatic Pumps

AP3 Submersible Pneumatic Pumps

AP3 Pumps are equipment designed for groundwater sampling and purging in monitoring wells and piezometers, ideal for environmental work and hydrogeological studies. Their compact and lightweight design enables efficient and safe operation, extracting water representatively without affecting the sample quality.

Manufactured from corrosion-resistant materials, such as stainless steel and high-durability PVC, AP3 pumps are suitable for demanding work environments, including slightly turbid or sediment-laden waters. Their modularity facilitates maintenance, cleaning, and installation, making them a reliable option for field technicians and environmental laboratories.

AP3 pumps are widely used in environmental monitoring, water quality control, and hydrogeological studies, offering precise and consistent results even in repetitive sampling campaigns or with multiple wells.

The air-driven AutoPumps are proven worldwide in thousands of remediation sites and landfills, making them the number one choice for environmental professionals due to their reliability, durability, performance range, and technical support.

All AutoPumps are ATEX certified for Zone 0.

• Positive air displacement.

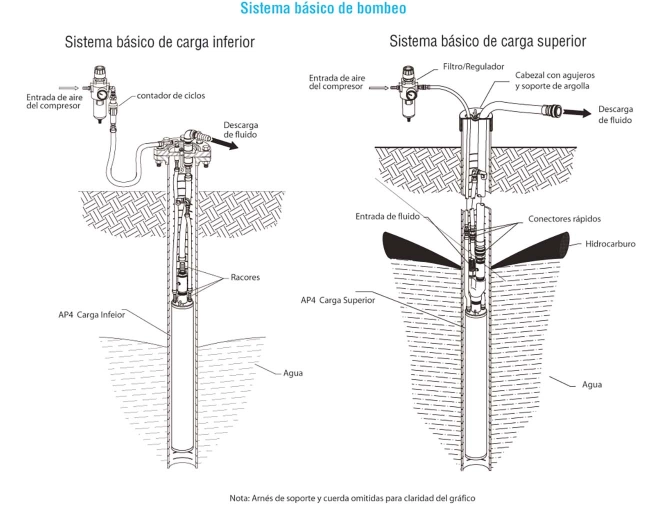

• Top and bottom fill design.

• Short and long bodies.

• Pump from approximately.

• Accessories available.

Envirotecnics offers on-site installation technical support.

We provide project sizing advice for landfill and industrial networks.

- Groundwater sampling in wells and piezometers

- Pre-sampling purging

- Environmental monitoring and water quality control

- Hydrogeological and geotechnical studies

- Sampling campaigns with multiple extraction points

Filling Cycle

The fluid enters the pump body by gravity, pushing the intake valve (1). The air exhaust valve (2) is open to allow air evacuation while the pump fills up.

At the maximum position, the float activates a mechanism that simultaneously triggers the closing of the exhaust valve and the opening of the compressed air valve (3).

Emptying Cycle

The increase in pressure inside the pump body causes the closing of the intake valve (1) and the expulsion of the liquid towards the network via the check valve (4).

The float's return to the low position triggers, contrary to before, the closing of the compressed air valve (3) and the opening of the air exhaust valve (2).

From then on, a new cycle would begin. This mechanical operation does not consume compressed air in the absence of fluid to pump.

- Based on the world-tested original automatic air well pump.

- Competitive flow rates and pumping capacities.

- Patented and tested design for superior reliability and durability.

- Handles solids, some solvents, hydrocarbons, and corrosive conditions beyond the limits of electric pumps.

Models

-

AP3 Pneumatic Pump, short top loading stainless steel ATEX

Ref. 5100000000190

-

AP3 Pneumatic Pump, short bottom loading stainless steel ATEX

Ref. 5100000000189