Over the years, the AutoPump AP2 has proven its durability in thousands of sites around the world, and it is for this reason that it is the # 1 choice for environmental professionals thanks to its reliability, performance range and technical support.

In addition to this, the key features include:

- The AP2 is a leader in durability, flow rate and depth capacity in an automatic pump for 2-inch diameter wells.

- It is designed for applications that require high input, such as pumping total fluids from wells contaminated with LNAPL.

- AP2s are ATEX certified for Zone 0.

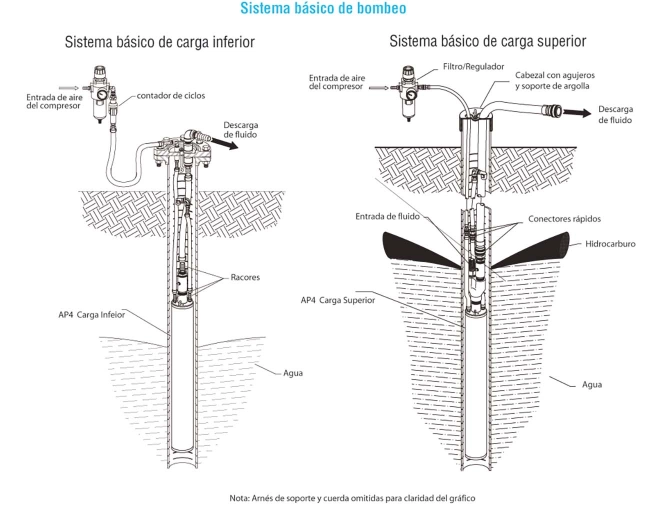

- The pump provides positive air displacement with top and bottom fill design.

- The AP2 has short and long lengths to match the water columns and meet different extraction requirements.

- The pump can be used from approximately 90 meters.

Tailored advisory service according to the type of pollutant, type of project and characteristics of the installation. We offer the complete installation and commissioning service of a complete ATEX system and data management system.

Contact us envirotecnics@envirotecnics.com or Tel: +34 872 080 542.