122 ATEX Interface Probe Solinst

The ATEX Solinst 122 Interface Probe is designed for the precise detection and monitoring of interfaces between liquids of different densities, such as water and floating petroleum products, in potentially explosive environments. Its ATEX certification ensures absolute safety in areas classified as hazardous, complying with the strictest safety regulations.

Manufactured with chemical-resistant and corrosion-resistant materials, this probe allows reliable measurements in monitoring wells, tanks, and bodies of water, even in demanding field conditions. Its compact and modular design facilitates installation, transport, and operation, optimizing time and effort for personnel.

The ATEX Solinst 122 probe is ideal for environmental technicians, hydrogeologists, and control laboratories, providing precise interface detection and reliable results for pollution studies and environmental remediation.

Available for rent.

- The determination of light non-aqueous phase liquids (LNAPL) and dense non-aqueous phase liquids (DNAPL) is quick and easy. The factory-sealed probe is pressure-proof (up to 500 psi) and tapes are available in a range of lengths from 30 to 300 m.

- The 16 mm diameter probe allows easy access through tight spaces and into narrow wells. The probe is designed to be used in different monitoring applications.

- 16 mm probe diameter

- Easy-to-insert 9 V battery

- Automatic shutdown after 5 minutes.

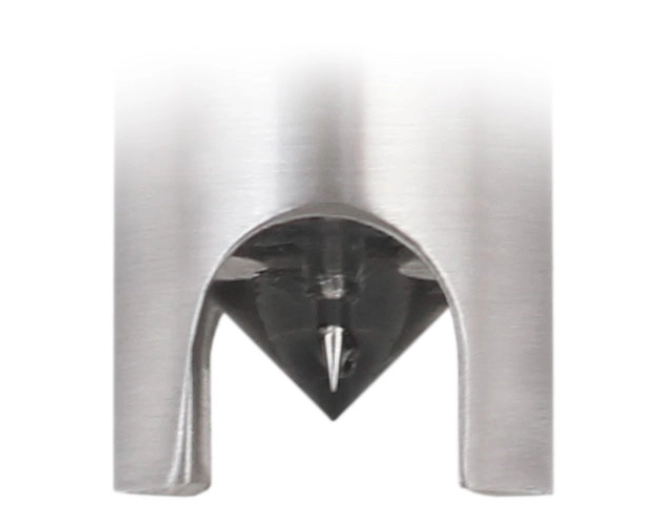

- Replacement tapes are interchangeable with probes 101 and 107. P8 Electrode The 122 interface probe uses the P8 electrode, 16 mm in diameter, made of stainless steel and pressure-proof up to 500 psi.

- The beam is emitted from a Hydex cone-shaped tip. The tip is protected by an integral stainless steel shield and is excellent for the vast majority of oil and petroleum product monitoring situations. Laser-marked flat tape

- The flat tape is extremely precise, traceable according to NIST and EU measurement standards. The easy-to-read marks on the 10 mm flat tape are laser marked permanently. The "dog-bone" shape of the tape prevents it from sticking to wet surfaces in wells.

- It is resistant to most chemicals, and the smooth surface of the tape is easy to clean and handle. LM2: feet and tenths of an inch, with marks every 1/100 feet. LM3: meters and centimeters, with marks every millimeter. Additional equipment Each standard-sized probe is provided with a ground pole, a cleaning brush, and a tape guide/reference point.

- A carrying case is optional. The tape guide can be used to provide support for a small reel in the well casing. It acts as a reference point that allows repeatedly accurate measurements, ensures the probe hangs in the center of the well, and protects the tape from damage. It is essential to use the ground pole to ensure safety and proper operation of electronic devices in all applications.

- Detection of water-petroleum product interfaces

- Monitoring in wells, tanks, and water bodies

- Hydrogeological studies and environmental remediation

- Quality control laboratories for liquids

- Applications in ATEX classified environments

Product (non-conductive liquid) = constant light and tone Water (conductive liquid) = intermittent light and tone Phase detection

To detect liquids, Solinst interface probes use an infrared light beam and detector. When the probe enters a liquid, the beam is refracted away from the detector, triggering an audible tone and light. If the liquid is an oil or non-conductive product, the signals are constant.

If the liquid is conductive (water), the water's conductivity completes the conductivity circuit. This nullifies the infrared circuit, and the tone and light are intermittent.

The electrode of the 122 interface probe provides precision up to 1.0 mm. The high precision allows the probe to detect the slightest trace of oil on the water surface.

The electronic elements include automatic circuit testing when using the “On” button; 120 hours of battery life; clear and high-precision signals. The circuits are powered by a single standard 9 V battery, located in the easy-access tray on the front cover of the faceplate.

Infrared refraction is used to detect liquids and conductivity to distinguish water. The optical and electronic sensors are precisely aligned at the same zero point. Obtaining product measurements To measure the thickness of a product layer, lower the probe into the well until the signal is activated. If there is a layer of oil-product on the water (LNAPL), the light and tone will be constant, indicating an air-product interface. Read the depth on the permanently marked tape. Lower the electrode further into the water, where the signals become intermittent, then pull it out and take a reading at the product-water interface.

The product layer thickness is then determined by subtracting the first reading from the second. If there is only water in the well, there will only be intermittent signals (water). The presence or absence of dense (sinking) non-aqueous phase layers (DNAPL) is determined by lowering the electrode again to the bottom of a well. If both the constant tone and light return, this indicates a non-conductive liquid. Measure the depth and continue lowering the probe until it touches the bottom and the tape goes slack. To determine the thickness of the DNAPL layer, subtract the first reading from the bottom depth reading.

- Reliable measurements in demanding conditions

- Safe for use in explosive environments

- High durability and chemical resistance

- Quick and easy installation

- Accurate results for environmental and remediation studies

- Modular design facilitates maintenance and transport

Models

-

Ref. 2000000000228

-

Ref. 2000000000226

-

Ref. 2000000000227

-

Ref. 2000000000230

-

Ref. 2000000000231

-

Ref. 2000000000232

Accessories