Pneumatic diaphragm pumps

Pneumatic diaphragm pumps

Pneumatic diaphragm pumps are designed to ensure efficient and continuous performance to reduce workload challenges and downtime.

Available for rent

These are devices designed to pump liquids efficiently and safely, using compressed air as a power source, making them ideal for environments where electricity is not viable or poses a risk. Their double diaphragm design allows for handling viscous, corrosive liquids with solid particles or shear-sensitive fluids, ensuring a constant and reliable flow in industrial and environmental applications.

These pumps are widely used in water treatment, mining, chemical, petrochemical, and pharmaceutical industries due to their self-priming capability, dry operation without damage, and handling of aggressive fluids. Made with corrosion-resistant materials such as polypropylene, stainless steel, PVDF, or aluminum, they ensure durability and prolonged performance even in demanding operating conditions.

With minimal maintenance and a modular design, Lasmert's diaphragm pumps offer flexibility in installation, easy part replacement, and long-term reliability, making them the ideal choice for critical pumping systems in industrial and environmental applications.

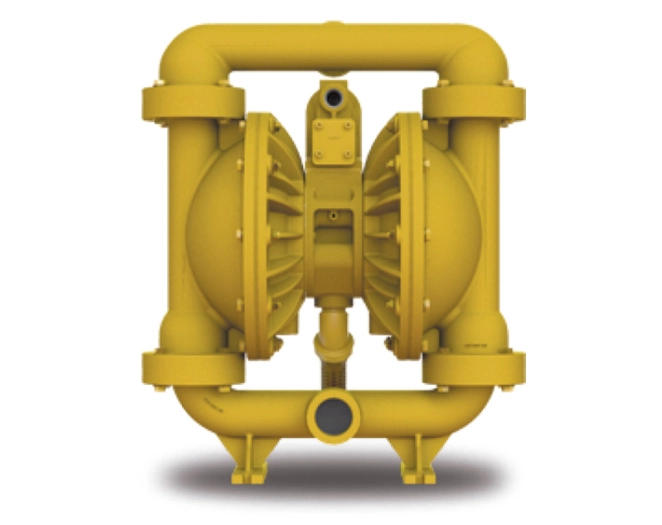

Metal Pumps

• Easy assembly

• Sturdy and long-lasting construction

• Wide range of sizes

• Multiple material options for your applications

• Submersible and portable

• Freeze-free

• Lubrication-free

• Operate in vacuum

• Sizes: From ½ to 3”.

• Materials: aluminum, cast iron, stainless steel, and Hastelloy.

• Max flow: 1033 lpm

• Max suction: 9.8m (Primed) / 5.8m (Non-primed)

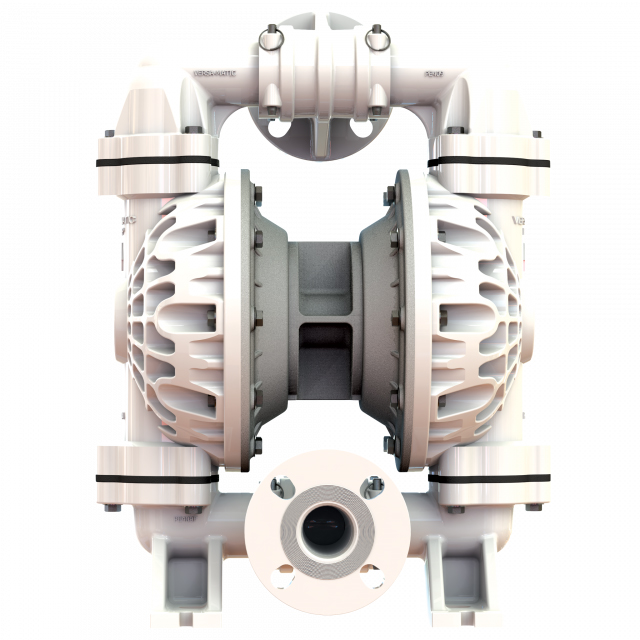

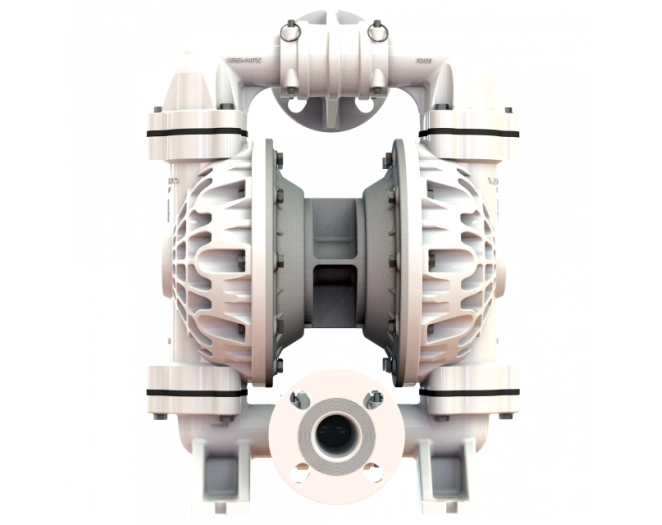

Plastic Pumps

• High chemical resistance.

• Wide range of sizes and materials.

• Submersible and portable.

• Freeze-free.

• Lubrication-free.

• Operate in vacuum.

• Size from ¼” to 3”.

• Materials: Conductive acetal, conductive polypropylene, polypropylene, PVDF.

• Max flow: 901 lpm.

• Max suction: 9.8m (Submerged) / 4.9m (On surface).

- Treatment of wastewater and industrial water

- Chemical and petrochemical industry: handling of acids, bases, and solvents

- Pharmaceutical and food processes: pumping of sensitive fluids

- Mining and extraction: transport of sludges, suspensions, and abrasive solutions

- Environmental and remediation projects: management of effluents and chemical reagents

They function using compressed air that drives two diaphragms alternately connected to a pumping chamber. The alternating motion creates suction at the inlet and discharge at the outlet, generating a continuous flow without the need for electrical power.

The design allows handling of liquids with solids, viscous or corrosive, because the fluid does not come into contact with sensitive moving mechanical parts. Moreover, dry operation is possible without risk of damage, and pressure and flow can be regulated by adjusting the air supply, offering precise pump control across all applications.

- Safe pumping in environments without electricity or electrical hazards

- Handling aggressive or abrasive liquids without affecting the equipment

- Reliable dry operation without risk of damage

- Versatile and adaptable to different flow rates and pressures

- Durability and minimal maintenance required

- Easy installation and field operation

Models

-

Pneumatic diaphragm pumps

Ref. 5100000000017

-

Pneumatic pump versamatic 1/2" alu/teflon ATEX

Ref. 5100000000018

-

Pneumatic pump versamatic 1" alu/buna ATEX

Ref. 5100000000019

-

Versa-Matic 1" Pneumatic Pump ALU/PTFE ATEX

Ref. 5100000000020